Your Cart is Empty

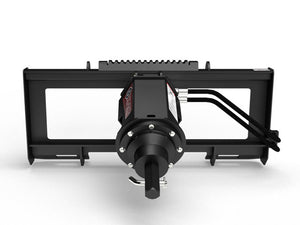

ADV36H

Virnig Auger Drive

$3,555.00

Revised 2/24

Auger Drive

PRODUCT CATEGORY: Skid Steer

2″ hex and 2 9/16” round output support up to 36″ diameter bits.

- HOSES ROUTED FROM TOP OF HOUSING FOR DEEPER DRILLING

- PLANETARY REDUCTION WITH 2″ HEX OR 2 9/16″ ROUND OUTPUT

- EATON® MOTOR WITH HYDRAULIC PRESSURE RELIEF PROTECTION

- BI-DIRECTIONAL AUGER ROTATION

| MODEL | AD36 |

| Overall Height/Width/Depth (Inches) | 20.5 / 47.3 / 35.5 |

| Maximum Standard/Tree Auger Bit Size (Inches) | 36.0 |

| Maximum Rock Auger Bit Size (Inches) | 18.0 |

| Recommended Flow Rate (GPM) | 15-25 |

| Output Torque @ 2000 PSI (ft.-lbs.) | 1820 |

| Output Torque @ 2500 PSI (ft.-lbs.) | 2275 |

| Output Torque @ 3000 PSI (ft.-lbs.) | 2730 |

| Output Torque @ 3500 PSI (ft.-lbs.) | 3190 |

| Output Speed @ 16 GPM (RPM) | 54 |

| Output Speed @ 20 GPM (RPM) | 67 |

| Output Speed @ 24 GPM (RPM) | 81 |

| Approximate Weight (Pounds) | 280 |

WHY DOES VIRNIG USE A PLANETARY GEAR REDUCTION SPINDLE OVER CHAIN DRIVE?

Virnig uses planetary gear reduction to transfer power from the motor to the output shaft and bit. Using a planetary provides several advantages over chain drive augers, including:

Increased Torque: Planetary typically provides higher torque output, which helps power through harder soil.

Greater Efficiency: Planetary reduction offers greater efficiency compared to chain drive. More of the power is translated into torque at the auger bit. This provides faster drilling times and lower fuel consumption.

Reduced Maintenance: Chain drive augers require regular maintenance to keep the chain properly tensioned and lubricated. In contrast, planetary reduction systems require less maintenance and have fewer parts that will wear and break over time.

Longer Lifespan: Planetary reduction auger drives tend to have a longer lifespan than chain drive augers, due to the reduced wear and tear on the drive system.

Overall, planetary reduction can offer greater drilling performance, efficiency, and longevity compared to chain drive augers.

WHAT ARE THE ADVANTAGES OF HEX OUTPUT?Hex augers have a hexagonal shape, which provides better torque transfer from the drive unit to the bit. This means hex augers can handle higher loads and are less likely to slip or strip compared to round output augers.

Hex augers have a more stable connection to the drive unit, which helps to reduce wobbling during operation. This results in smoother operation and more precise digging.

It’s easier to attach and detach auger bits on a hex drive. A round drive requires aligning two circles properly. Also, Virnig Augers with hex output secure bits with a pin, which is easier to attach and remove than a bolt and nut used on round auger drives. This reduces downtime and increases productivity.

WHY WOULD SOMEONE CHOOSE AN AUGER WITH ROUND OUTPUT?Someone may choose round over a hex auger drive for several reasons. Round auger drives have been around the longest and switching to hex would require replacing all their round bits with hex collar bits. In some applications, hex may not be necessary and a round auger drive may be sufficient. Some users may simply prefer the feel of a round auger drive and may have more experience using them.

Overall, both round and hex auger drives have their advantages and disadvantages, and the choice between the two will depend on the specific needs and requirements of the user.

DOES THE VIRNIG AUGER DRIVE USE A HEX OR ROUND OUTPUT?The Auger Drive has a 2” hex or 2-9/16” round output.

CAN I USE THE AUGER DRIVE WITH HIGH FLOW?The Virnig Auger Drive (AD36) motors are rated for 15-25 GPM with zero overflow tolerance. Operating higher than 25 GPM will void the warranty and can cause catastrophic failure.